WORLDSENSING

The Connected Infrastructure Solution

Loadsensing is a monitoring and data acquisition system that combines state-of-the-art wireless monitoring devices and advanced software tools. It is widely recognized as a leading solution for connecting and monitoring infrastructures in remote locations.

Loadsensing devices are battery-powered and equipped with long-range, low-power wide area network (LPWA) radio communications and are compatible with a wide range of geotechnical sensors. The software component is web-based and facilitates real-time data capture and analytics. It is also possible to set automatic alarms to make operations safer.

Mining and construction companies and operators of bridges, tunnels, dams, railways and many other inaccessible assets can now work with reliable data. Having access to this information and real-time insights enables operators to anticipate needs, manage their workforce, diminish risks, and even prevent disasters.

Ensuring Safety and Efficiency

Long-term planning is a challenge for any mining operation, and geologists and engineers rely on accurate, timely data from surface piezometers and wells to ensure productivity and safety. Teams have to travel to the mine regularly to collect manual readings, and this process is time-intensive and difficult, and puts team members and equipment at risk.

Loadsensing technology eliminates these operational challenges and safety obstacles by allowing mining teams to collect data in real time and remotely, so they not only enhance their safety, but also reduce the time they spend collecting mine readings. Team members, systems, and sensors are perfectly linked to create a safer, more efficient operation.

Complete Operational Intelligence

What can mining operations accomplish with Loadsensing technology? The options are nearly endless, but here are a few key advantages mines can realize with this customizable software solution:

- Manage, maintain, and monitor key assets from a remote location

- View all mining operations from a completely visible viewpoint

- Make decisions based on reliable intelligence using data insights

- Eliminate the need for expensive cabling

- Integrate sensors and third-party systems with ease

Manage environmental risks, reduce monitoring costs, enable predictive maintenance, ensure workplace safety, and more with Loadsensing technology. For further information about this innovative option, contact us at RAMJACK Technology Solutions today.

What you need to know about Loadsensing

How it works

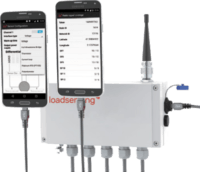

Loadsensing is comprised of both wireless devices and a software suite. All hardware units are compatible with most geotechnical sensors. Once sensors are connected to the wireless Loadsensing unit and the system’s gateways are properly installed on site, they are ready to receive, store and send data. At the same time, all this data is available through a web interface which enables users to monitor the site or infrastructure remotely. During the installation process of the wireless units, an Android app enables customers to set up and visualize the performance of each device. They can set sampling rates, check radio coverage wherever the units are installed and view real-time data captured by the sensors.

Software Suite

The Loadsensing Software Suite includes a service ensuring that clients can access their gateways even when the devices are behind a firewall or in a private network. Furthermore, the software suite features asset, network and device management tools which facilitate remote site maintenance. All data is displayed on an intuitive web interface which can be accessed by any internet-connected device. Moreover, a set of analytics tools are included for easy reporting and alarm configuration.

Long-Range

Due to their long-range capabilities, Loadsensing wireless devices are the perfect solution for harsh environments or difficult-to-access sites. The Loadsensing device network is complient with CE/FCC-certifications and features ultra low-power capabilities in ISM bands. This is why the Loadsensing system achieves a communication range of several kilometers between nodes, one of the highest in the market, of up to 9 miles/15km.

Low-Power

Loadsensing wireless units have been designed to function autonomously and unattended during long time periods. The system’s low-power components remain on sleep mode and are only activated at predetermined times. Once a unit has gone into active mode to read data from a sensor and sends it to a gateway, it goes right back into sleep mode. There is no other long-range wireless system available featuring batteries that ensure life spans of up to 8 years.

Wireless Sensor Network

Loadsensing wireless sensor networks can be easily expanded by adding new wireless units to the network. The advanced network management tools allow for the automatic addition of new nodes in the network in a transparent way. Moreover, the network protocols have been designed to be highly scalable, and a single Loadsensing gateway can manage up to 500 nodes.

Network latency and packet loss ratios are also minimal due to the robust implementation of the protocols. Security is central to the protocol implementation to ensure a very resilient wireless system. The most advanced encryption mechanisms have been used to ensure the solution is ideal for mission critical applications.

Wireless data units

Each Loadsensing unit is a smart node within the wireless sensor network. All nodes act as a datalogger to their own sensor. The wireless units are high precision digitizing parts offering complete signal measurements with up to 5ch of high resolution and are capable of reading at a sampling rate of 30 seconds to 24 hours depending on project requirements. The units are easy to deploy, very robust and they dont require recasing as they already hold relevant certifications. Loadsensing units are IP67 certified and tested from -40C to +80C.

Cost-effective

Loadsensing’s economic value becomes clear when compared to equivalent traditional approaches: inspecting 100 easy-to-access and 10 difficult-to-access structural sites once per month over a period of 10 years can cost hundreds of thousands or even millions of Euros. Loadsensing setup and operating cost are typically 20% lower, with the added value of around-the-clock monitoring.

Remote data-collection and real-time monitoring

Ensuring safety and efficiency for mining operations

NETWORK AND ASSET MANAGEMENT SOFTWARE

- Network communications configuration and control.

- Wireless data unit and sensor attributes display.

- Wireless data unit configuration.

- Sensor data in real time.

- Conversion of raw sensor data in engineering units.

- Manual and automatic data download in .csv.

- Data transmitted in a secure manner.

- Remote change of sensor’s sampling rate.

- Data accessible through Modbus TCP.

- Able to push data on user FTP.

DLOG APP

- Simple and fast connection to wireless node.

- Runs only on Android devices.

- Easy sensor configuration: ID, sampling rate, sweep, etc.

- Checks radio signal coverage.

- Records coordinates (GPS).

- Downloads data from wirless data node and sends it to Android device by e-mail or saves it.

- Takes current reading.

- Updates wireless data node firmware.

MAIN SPECIFICATIONS

- One RS485 channel and two SDI-12 channels.

- Power supply: 12 V DC up to 120 mA.

- RS485 full or half duplex supported.

- Suitable for a chain of up to 30 biaxial in-place inclinometers.

- Modbus RTU RS485.

- Supported sensors: RTS, Sisgeo and Geosense digital inclinometers.

At RAMJACK Technology Solutions, we offer solutions from Loadsensing to clients in Africa, Europe, and the Middle East.