Summary

Welcome to part 4 of our Geotechnical Monitoring campaign, where we cover the critical role of instrumentation — the foundation that enables accurate, reliable data collection across all facets of monitoring. You'll learn the key features, technologies, and benefits that matter most to mining operations: from precision measurements and durability in harsh environments, to integration capabilities and how the right instrumentation selection drives better safety outcomes, operational continuity, and long-term planning success.

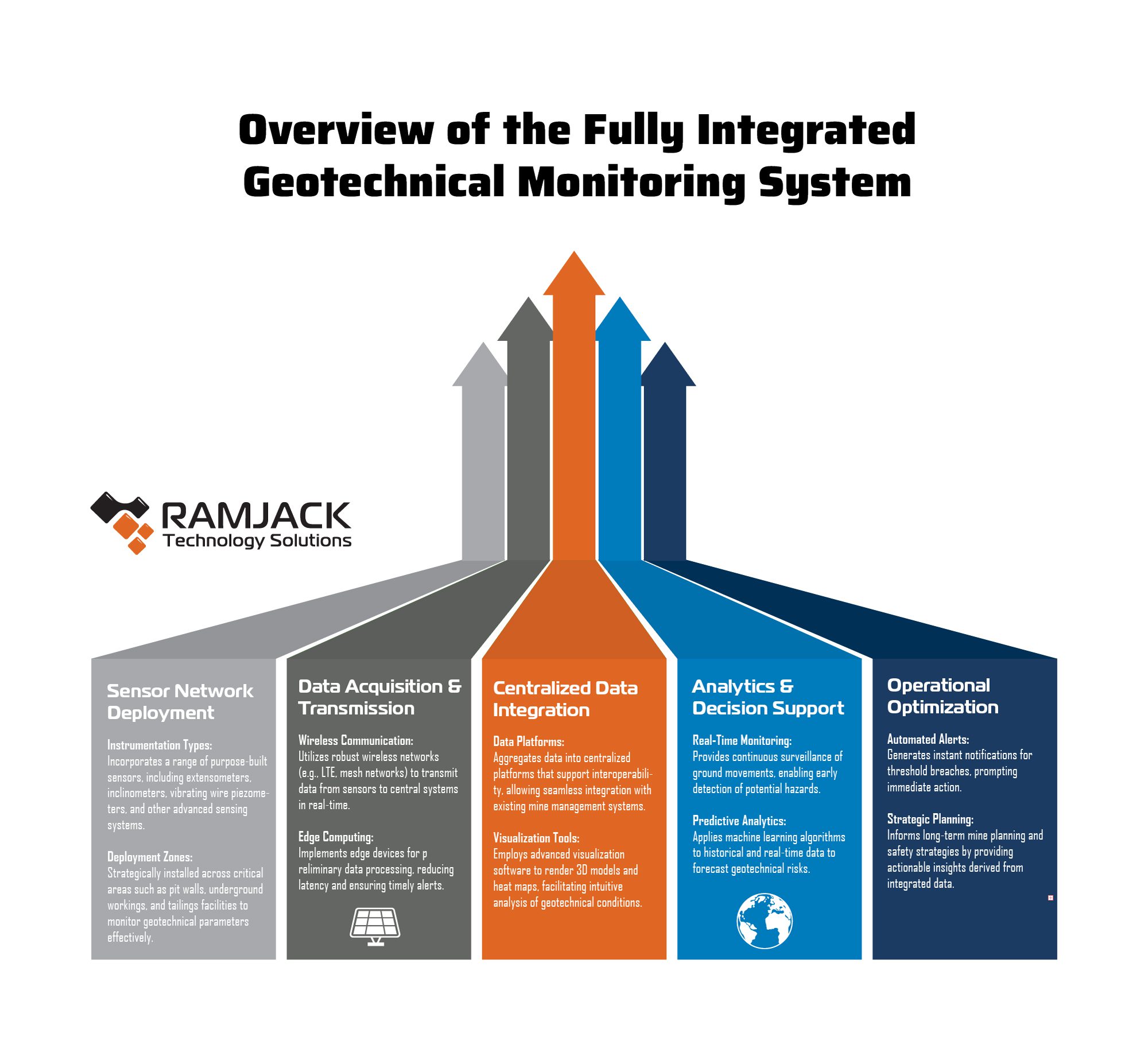

A successful geotechnical campaign depends on the ability to collect, integrate, and act upon high-quality data from across the mine site—both surface and underground. Ramjack’s technology integration strategy makes this possible by deploying purpose-built instrumentation connected through an intelligent, interoperable system architecture, and visualization software. Purpose-built instrumentation is essential for seamless capture and integration of all your monitoring data, enabling continuous surveillance of unplanned movement in the environment around you. Whether monitoring the mine face or inaccessible areas, our solution ensures your team sees what’s going on below the surface around the clock. Instant alerts empower swift responses and facilitate ongoing safety optimization strategies.

By targeting all critical geotechnical domains—including seismicity, stress redistribution, deformation, and hydrological changes—our approach transforms instrumentation from isolated tools into the foundation of proactive risk management.

Multidimensional Instrumentation for Complete Monitoring

Ramjack’s solution supports real-time surveillance across a range of geotechnical conditions, through sensors purpose-built for:

- Seismic activity – Monitoring rock fall potential and dynamic ground behavior.

- Rock stress and deformation – Capturing load responses and movement through instruments like extensometers and stress cells.

- Rock movement – Measuring displacement in slope walls, underground openings, and high-risk zones.

- Groundwater and pore pressure – Using piezometers and other relevant instrumentation to understand hydrogeological influences on slope stability.

- Backfill monitoring – Tracking fill strength and settlement in real time.

- Tailings dam integrity – Integrating purpose-built sensors and gauges to measure movement and soil resistivity for continuous risk assessment.

Key Features of Ramjack’s Instrumentation Integration

What sets Ramjack apart is not just the instrumentation or the strategy behind which technology to choose, but how it’s integrated into your unique mining operation, with the existing tools you have:

- Continuous, real-time data acquisition from all sensor types, even in inaccessible or hazardous zones.

- Wireless telemetry and edge computing for low-latency transmission and preliminary data filtering.

- Centralized platforms that unify all data streams into a single geotechnical dashboard.

- Advanced visualization (3D models, heat maps, geospatial overlays) for intuitive interpretation of geotechnical trends.

- Interoperability with mine planning systems and operational control platforms.

Operational Benefits and Strategic Value

Ramjack’s integrated instrumentation strategy yields tangible operational and strategic value by enabling mines to anticipate and respond to geotechnical hazards in real time. This proactive approach improves safety outcomes, reduces unplanned downtime, and enhances decision-making across technical disciplines.

- Enhanced Safety and Risk Mitigation

- Real-time monitoring of stress allows geotechnical teams to identify early warning signs of instability—often hours or days before failure.

- Systems are configured with automated threshold alerts tied to site-specific geotechnical trigger action response plans, allowing immediate communication, mitigation, and evacuation if required.

- By covering inaccessible areas, such as unsupported headings, highwalls, or deep tailings embankments, Ramjack’s remote instrumentation improves safety without compromising data quality.

- Estimated Value: We estimate that preventing a single ground control incident that results in injury or equipment damage can save between USD 100,000 and 2 million, depending on severity and response costs.

- Productivity Gains Through Reduced Downtime

- Advanced instrumentation supports early detection of potentially disruptive ground movements, allowing operators to schedule remediation (e.g., scaling, bolting, or backfilling) during planned maintenance windows rather than halting production reactively.

- In underground operations, better understanding of backfill behavior and stope closure enables optimized sequencing, reducing idle equipment time and re-entry delays.

- On surface mines, continuous slope monitoring facilitates longer safe working windows and reduces over-conservatism in exclusion zones, thus maintaining equipment utilization.

- Estimated Value: We estimate that avoiding unplanned shutdowns in a large-scale mining operation can yield USD 50,000 to 500,000 per event, depending on ore throughput and affected equipment.

- Improved Asset Management and Infrastructure Longevity

- Monitoring deformation in shaft infrastructure, pit walls, and tailings embankments allows for predictive maintenance rather than reactive repair.

- Timely intervention based on data trends reduces the likelihood of costly remediation (e.g., wall buttressing, tailings dam reinforcement).

- Estimated Value: We estimate this improved infrastructure planning and risk mitigation can extend asset life by several years, delivering long-term cost avoidance in the range of USD 1–5 million over a mine’s lifecycle.

- Decision Support and Strategic Planning

- Centralized data integration enhances collaboration between geotechnical, production, and planning teams.

- Historical data trends feed into geotechnical models and mine planning software, improving design reliability and forecast accuracy.

- Supports compliance with regulatory frameworks by providing auditable records of monitoring and response actions.

In conclusion, instrumentation is not simply a component of the geotechnical campaign—it is the nervous system of a proactive safety and stability strategy. Ramjack’s integration-first philosophy ensures that every sensor contributes to a holistic understanding of ground conditions, enabling faster, smarter decisions that protect people, infrastructure, and production.

Stay tuned for Part 5, where we focus on the integrated system that brings everything together: instrumentation, telemetry, and networking. This power-combo enables real-time monitoring and decision-making. This is where data transforms into actionable intelligence, offering 3D visual context and site-wide situational awareness that empowers mine operators to manage geotechnical risks confidently and effectively.

Are you ready to see the unseen and protect your operation with confidence?

Contact Ramjack today to discuss building a geotechnical monitoring system tailored to your mine.