INKONOVA

Our Tech

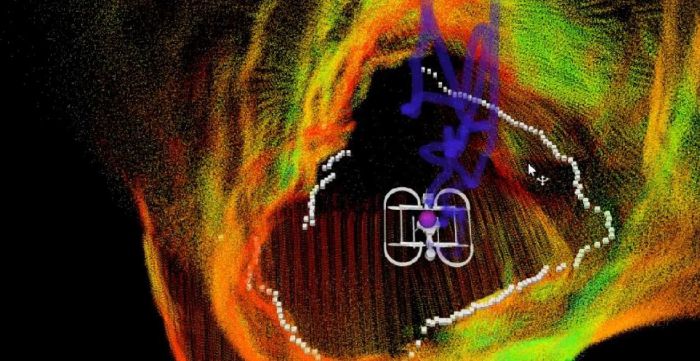

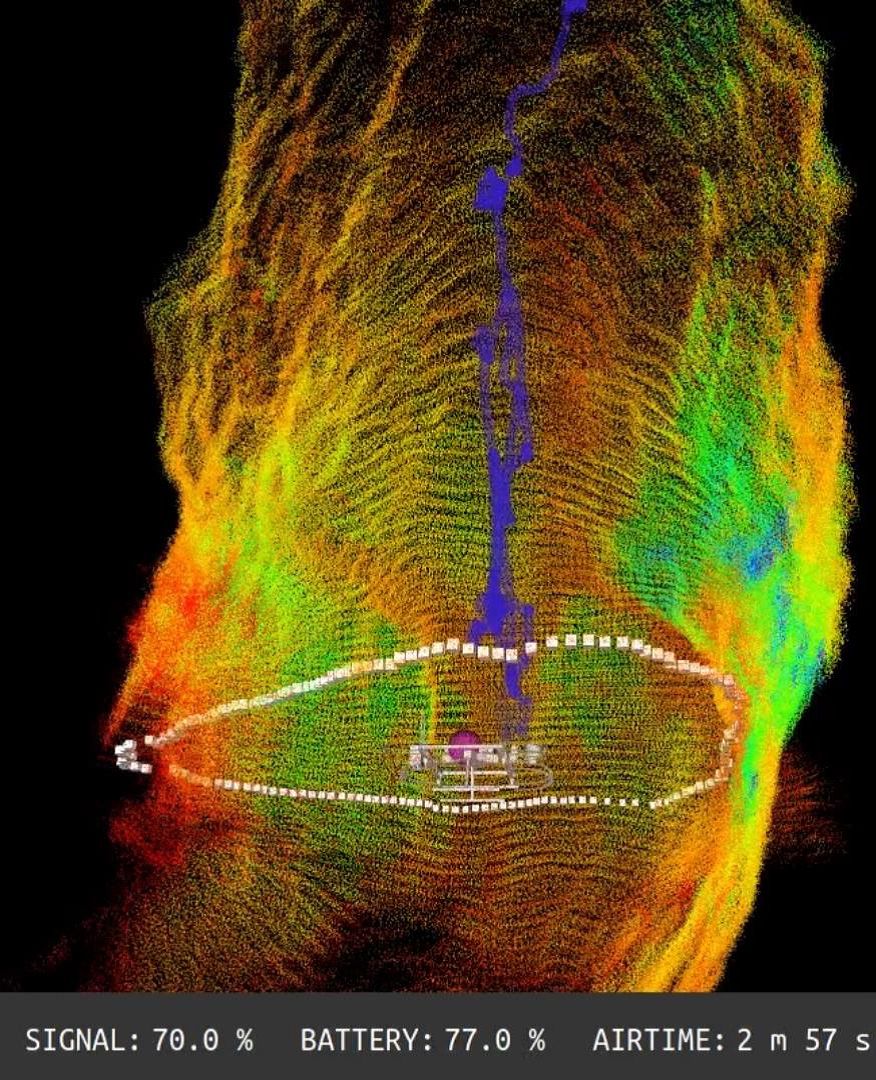

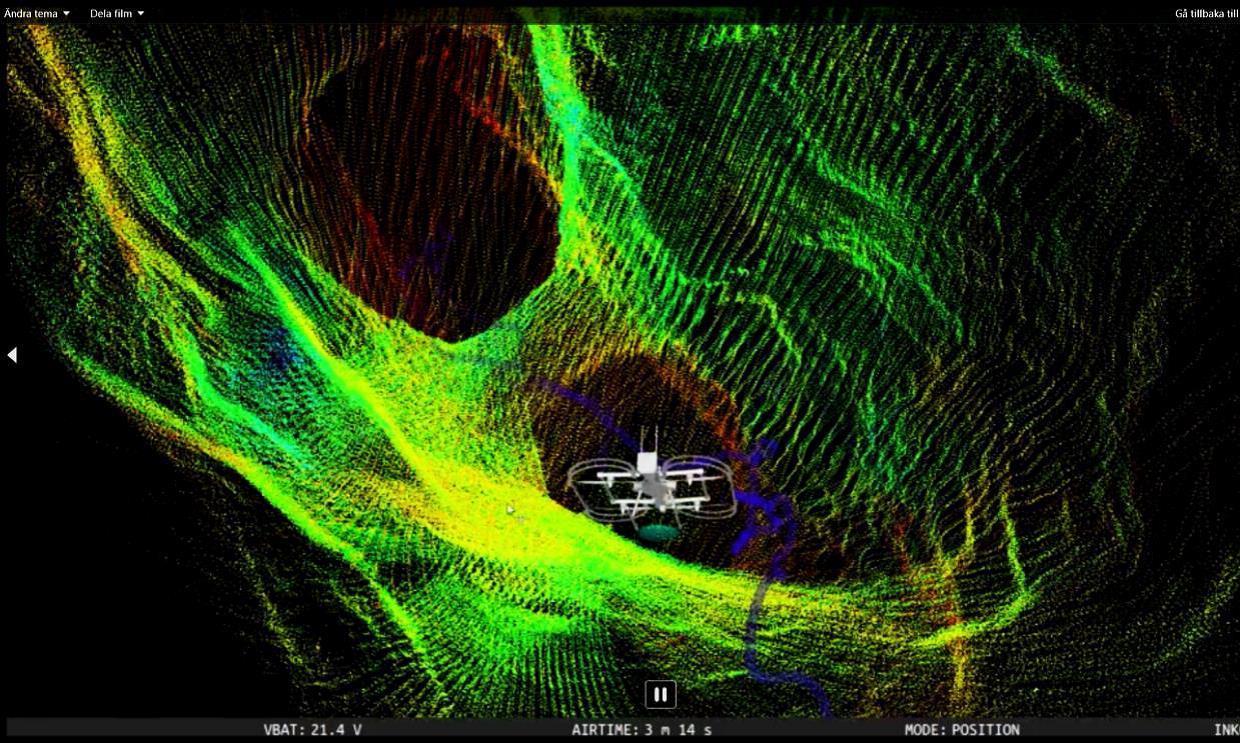

- Real-time laser mapping, the complete solution for underground exploration

- Access GPS-denied, constricted and inaccessible zones

- Laser based Beyond-Line-Of-Sight (BLOS) operation with Dual SLAM

- Integration in mining automation systems and routine flights

Inkonova offers real-time, underground mapping and data acquisition technologies unlike any other. Safe and efficient inspection, mapping, and data capture underground is now possible with our real-time, 3D visualisation innovations. Our agile, smart-drone technologies give you real-time access to areas that range from just below the surface, to deep, dangerous and previously inaccessible. We utilise non-GPS localization, SLAM and 3D pointcloud generation tools. Unleash your team’s exploration capabilities with Inkonova!

What we Do

Inkonova has pioneered the only real-time mapping and data acquisition tools for underground mining. Our technologies are the most cost effective, agile, and time-efficient tools available on the market to survey and visually inspect underground tunnels and formerly inaccessible areas. Exploring beyond-line-of-sight gives true all-around awareness!

OPERATIONAL BENEFITS

Simultaneously survey and map underground while tracking your device beyond line-of-sight. Mapping remote areas is now a quick, simple, and affordable process! Inkonova’s real-time mobile-mapping offers many operational benefits:

REDUCE CARBON FOOTPRINT

ACCELERATE PRODUCTION TIME

INCREASE SAFETY OF HUMAN WORKFORCE

MINIMISE EXPLORATION RISKS

INCREASE OPERATIONAL EFFICIENCY, EFFECTIVITY & PROFITABILITY

OPTIMISE SEARCH & RESCUE MISSIONS

REDUCE OPERATIONAL COSTS

UNLOCK FULL POTENTIAL OF INACCESSIBLE AREAS

OPTIMISE PRODUCTION FLOW

The most cost & time efficient way of inspection, mapping & data acquisition in underground mining

- Batonomous Laser Scanning Suite

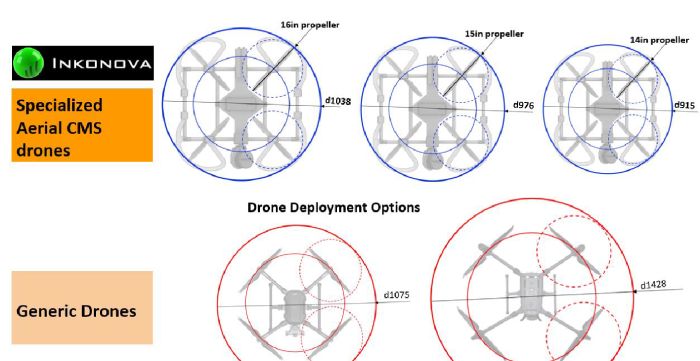

- Flexible Deployment Options

- Access the Inaccessible

- 3D Mapping and Inspection Data Acquisition & Data Processing

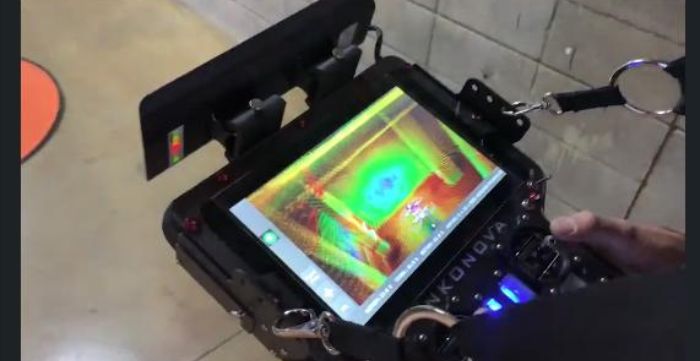

- Smart and Intuitive Operation

Gather critical data and decision-making support cost-effectively

- Both aerial (drone) and ground (handheld, vehicle) options available

- Provides geological surveys more safely, faster and further

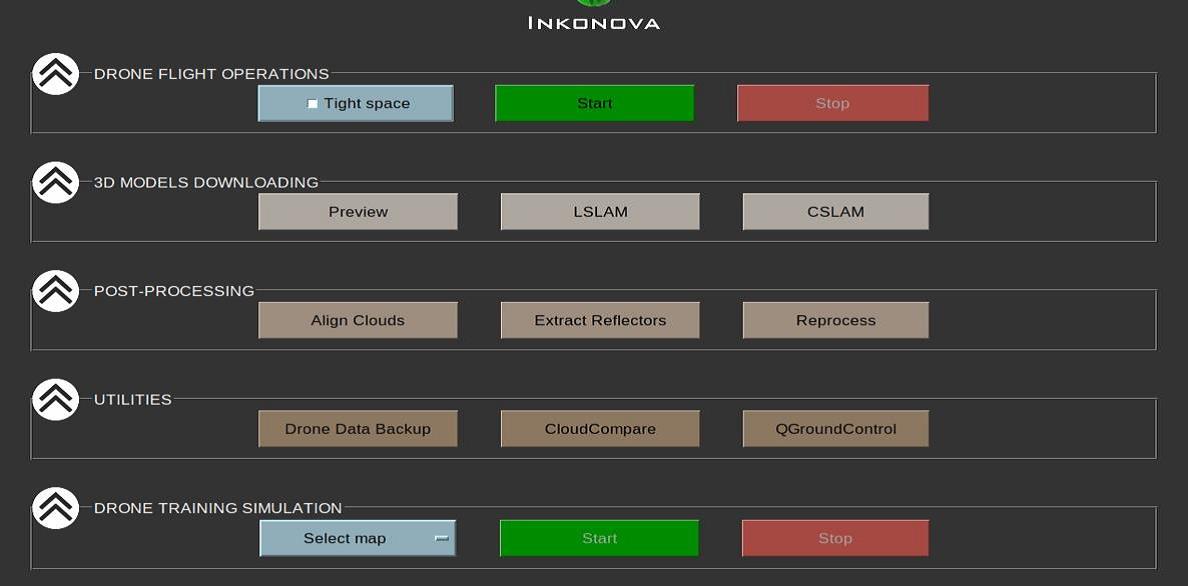

- Semi-autonomous workflow:

- Prepare safe mission (assemble and arm)

- Execute multiple-task mission:

- Navigate, gather, process and display all simultaneously

- Deliver immediate results: download data directly after landing

- Drone Enabled

- Handheld

- Vehicle mounted (optional)

- Back Pack mounted

- Reduce number of hours surveyors spend underground

- Free surveyor time to focus on higher value tasks

- Unlock the value and potential of old mines

- Streamline decision-making process with real time data

- Inspect historical geological structures to enhance future mining design

- Autonomy Level 1 (equivalent to GPS Position Hold but UG)

- Autonomy Level 2 (waypoint navigation)

- Autonomy Level 3 (fully autonomous exploration)

- Automated cloud merging software increases efficiency and precision

- Dual SLAM 3D mapping offers superior reliability

- Real-time visualisation and in-flight point cloud processing provide instant 3D map

- Insightful, user-friendly app with maps and operational info

- Automated geo-reference control points offer precise geo-positioning

- Collision avoidance system allow safe and confident piloting

- Internal flight logging provides historical journey records

- Low battery warning system

Application Examples

Monitor and maintain ore-passes and shafts

- The heart of material transport. Conditioned ore-and waste-passes drastically reduces transport carbon footprint

- Monitor shafts and rock/waste passes

- Flow optimization

- Proactive reconditioning

Accident Analysis and Assessment

Optimise post-incident analysis with automated aerial inspection for better decision making and faster production ramp up time.

Volume calculation of stock pile

Inaccessible UG scanning

Autonomous Exploration

Integration into Mining Workflow

Predictive maintenance: automated/ai Information extraction

Geotechnical Structure Detection

About Inkonova

Based in Stockholm, Inkonova began innovating tilt-rotor systems for racing drones in 2015, creating one of the world’s fastest drones (faster than a Lamborghini) before switching focus to becomes the world’s first developer of drone solutions for underground mines. Today, Inkonova develops both underground robotics for inspection as well as 3D mapping solutions with SLAM-based technologies.

At RAMJACK Technology Solutions, we offer solutions from Inkonova™ to clients in Africa, Europe, the Middle East and Latin America.