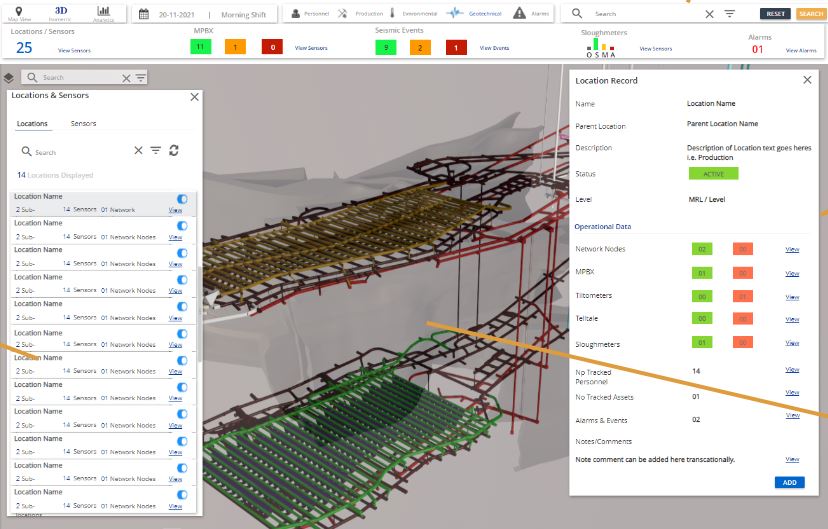

Accurate knowledge informs good decisions. In a mine, all too often, the information needed to make good decisions is not available. And, even when the information is available, the context is not. Effective mine management requires the right information be provided to the right decision maker at the right time – and with the right context. For this reason, RAMJACK’s solution set emphasises real-time information with accurate and easy to understand, 3D visualisation.

To ensure useful and reliable availability of information, interoperability of systems is critical. For technologies to be collaborative, all data needs to be stored in an open standard database and/or be accompanied by APIs and file-transfer systems for ease of integration and data sharing.

To ensure timeliness of information and effective support to decision making, systems need to be ‘always on’, continuously monitoring the status of all activities on the mine. Alarms need to be addressed as part of the mine’s Short Interval Control process and alarm thresholds need to be tightened to achieve the next stage of efficiencies.

Mines that are advancing along a digitalisation journey or embarking on an automation strategy will undoubtedly generate significant amounts of data. Organising vast amounts of data is a challenge, but accessing and using this data for continuous improvement purposes is an even bigger challenge. The most effective way to provide context to large data sets and to share data across departments is a 3D representation of the mine annotated with real-time status updates, sensor readings and production statistics. Representing mines in this visual way improves the user’s understanding of the situation and simultaneously improves decision-making and communication throughout the mine.

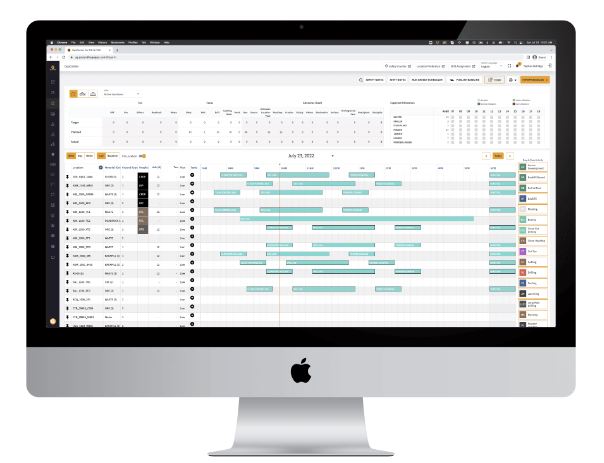

RAMJACK’s Visualisation and Information Management System is an independent solution that sits on top of both integrated and disparate Monitoring and Management Systems to integrate information horizontally (across the value chain) and vertically (to include field / sensor data) into one coherent platform. Fully integrated in this fashion, the system breaks down departmental ‘silos’ by providing a simple, scalable and configurable central view, complete with all the pertinent mine information required for advanced decision-making related to production, maintenance and safety.