Challenge

- Difficulties analyzing truck performance normalized for work intensity

- Limited visibility on truck performance between maintenance events

Objectives

A Colombian coal producer wanted to understand:

- How successful targeted maintenance interventions were at restoring equipment efficiency

- How haul truck models could help prioritize equipment maintenance

Technology

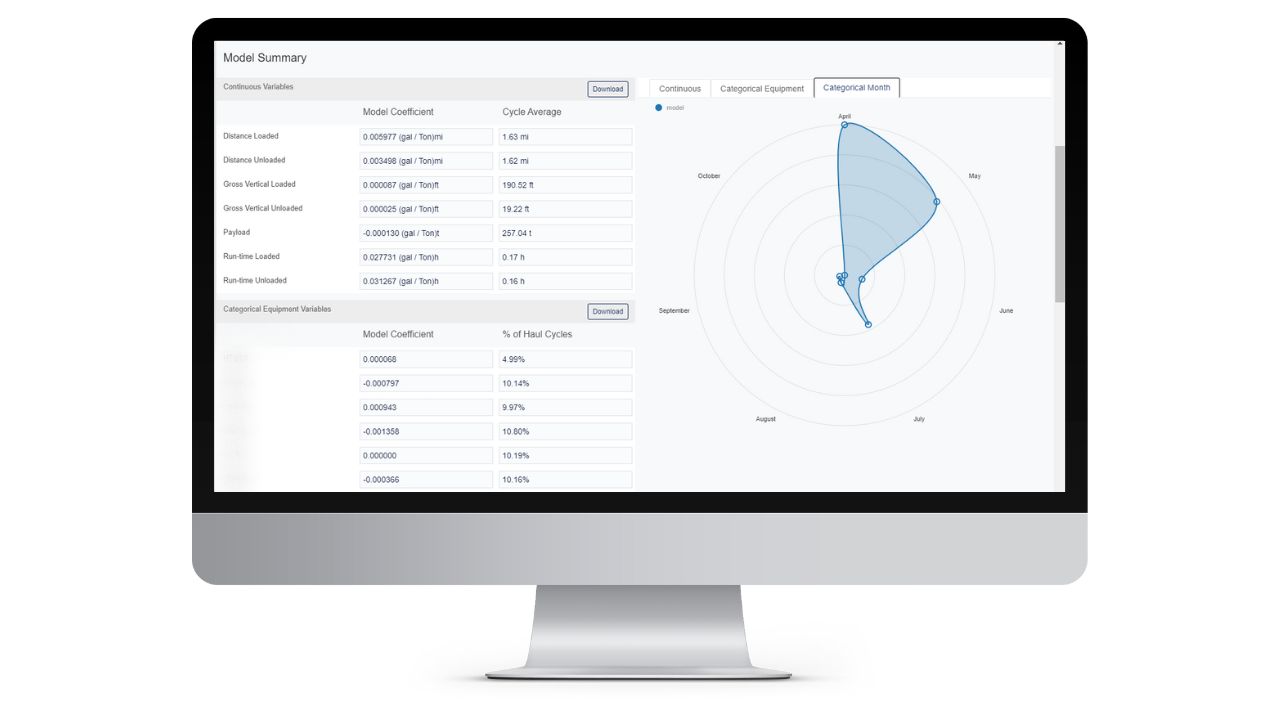

Cascadia Scientific produces models that isolate for the impact of haul truck health on overall haulage efficiency. Maintenance teams then use these models to perform service interventions on underperforming trucks.

Implementation

Cascadia data scientists monitor the underlying efficiency of equipment and trigger interventions in response to negative step chances and poor performance. Upon inspection, issues have been uncovered ranging from faulty injectors to clogged air filters, to fuel leaks. If not for Cascadia Scientific these trucks would have stayed in operation, consuming excess fuel and increasing the risk of a more serious failure.

Results

- Efficiency-triggered maintenance saved over 24,000 litres annually per truck

- Failed and/or failing components were identified before catastrophic failure of machines occurred

- Reduction in 71 Tons of C02 annually per truck

Modelled Truck Efficiency detects clogged air filter on a CAT 793