PLAYERS

Mining Operation: Located in Turkey, this gold mine is one of the country’s key open-pit mines, contributing significantly to the region’s mineral production. They utilize modern mining practices aligned with international environmental and safety standards. The operation plays a vital role in the local economy, providing employment opportunities and supporting community development initiatives.

Ramjack Technology Solutions is a specialized system integrator formed to support global mining operations by monitoring, managing and optimizing anything that matters in real time. With a vast range of experience in mining technology and long-standing, strategic partnerships with the world’s best mining technology manufacturers from across the globe, Ramjack provides a suite of best-of-breed solutions and specialized services that solve the key operational challenges that mines face today – improving safety, enhancing sustainability and increasing productivity.

Cascadia Scientific improves mine haulage sustainability and helps customers address their most pressing needs through data-driven decision support. Cascadia Scientific strives to minimize the carbon footprint of heavy mining equipment and will continue toward this path until our industry achieves complete decarbonization. Their technologies apply high-accuracy fuel flow meters and machine learning to deliver real-time, actionable insights into mobile equipment performance. Designed specifically for mining, Cascadia’s system enables mine sites to identify inefficiencies, act with precision, and continuously improve and maintain efficiency gains over time.

CHALLENGE

The mine was experiencing reduced haulage efficiency due to areas with poor road conditions that negatively impacted truck performance, fuel efficiency, and overall production output. Operators had identified recurring performance issues on several segments of the main haul road but lacked high-resolution data to quantify their impact or evaluate corrective actions. The challenge was to isolate and assess the effects of road design deficiencies so they could be corrected.

HIGH LEVEL SOLUTION

To address performance issues linked to haul road conditions and to learn more about road utilization, Ramjack deployed a targeted monitoring initiative to identify problem areas using heat maps, and evaluate the effectiveness of road design changes. The project focused on capturing and comparing haulage performance data from four selected trucks before and after repairs were made to four known “hot spot” segments. By analyzing this high-resolution telemetry and fuel flow data, the mine wanted to be able to quantify the impact of road improvements and extrapolate the results to estimate potential productivity gains across the entire 24-truck fleet, and potentially extend these insights to other mobile equipment and future applications at similar operations.

SOLUTION DETAILS

Ramjack leveraged Cascadia Scientific’s high-accuracy fuel flow meters and vehicle telemetry systems to evaluate haulage performance on haul trucks before and after targeted road repairs.

Cascadia Fuel Flow Meters

Cascadia’s fuel flow meters before, and after, as installed on the customer’s haul trucks

Cascadia improves haul road performance, measured by fuel efficiency.

Every truck becomes a mobile sensor. Cascadia’s system maps fuel consumption across each segment of the haul route and flags abnormal patterns. Dispatchers and planners gain a live, data-driven view of which roads are inefficient – and why.

This helps mines to:

- Identify the fuel and efficiency impact of every dispatching decision

- Quickly pinpoint and respond to high fuel burn across the pit

- Support ESG goals by focusing on areas with the highest fuel consumption

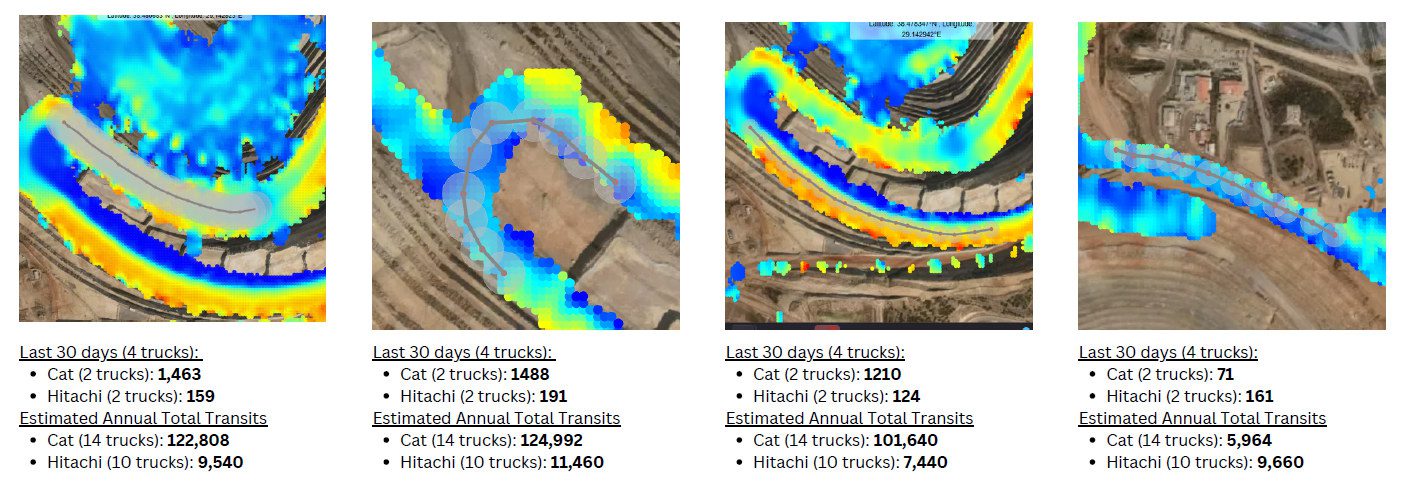

Over a 30-day period, road utilization data was collected at each of the four identified “hot spots”:

- Lower Ramp

- Roundabout

- Upper Ramp

- Support Ramp

This data was used to establish a performance baseline, predict usage patterns, and quantify the potential benefits of road segment improvements.

This baseline was critical in isolating external variables, ensuring a more accurate assessment of the repairs’ impact, and enhancing the overall analysis of haul road performance. Cascadia’s precision fuel flow technology, when integrated with real-time vehicle telemetry, enables mining operations to pinpoint specific road segments that negatively affect fuel consumption and vehicle efficiency—providing actionable insights for operational optimization.

RESULTS

The evaluation revealed a 270-meter haul road segment in critical need of regrading and slope correction, with anticipated benefits including improved fuel efficiency and shorter cycle times. Using Cascadia Scientific’s fuel flow and telemetry data, pre-repair analysis showed estimated fuel savings of 1.17 liters per loaded pass for Caterpillar trucks and 1.97 liters for Hitachi units, translating to a projected annual fleet-wide fuel savings of approximately 93,271 liters. Operational data at the beginning of the project highlighted key performance issues, including 442 acceleration surge violations, 188 excessive acceleration events, and 101 overweight cycles. Notably, excessive idling, RPM violations with the dump body raised, and overweight payloads were identified as the most impactful operational risks. Additionally, high vertical acceleration zones along the haul road signaled uneven terrain contributing to increased mechanical stress, reduced hauling efficiency, and extended cycle times. A post-repair audit is recommended to validate the projected improvements and support ongoing optimization.

| Category | Details | Impacts / Insights |

| 1. Hot Spot Identification | - 270 m section flagged for regrading and slope correction | - Potential fuel and cycle time optimization- Audit recommended post-repair |

| 2. Fuel Consumption Analysis | - CAT trucks: 1.17 L savings per loaded pass- Hitachi trucks: 1.97 L savings per pass- Projected annual fleet savings: 93,271 L | - Significant operational savings- Justifies investment in road maintenance |

| 3. Critical Operational Events (Jan 2025) | - 442 acceleration surge violations- 188 excessive motion acceleration- 101 overweight payloads- 35 rolling violations | - Excessive idling, dump body RPM violations, and overweight cycles identified as high-risk behaviors |

| 4. Terrain Impact | - High vertical acceleration zones detected via telemetry | - Indicates surface irregularities- Causes component wear, cycle delays, and reduced efficiency |

BENEFITS SUMMARY

Fleet-Wide Efficiency Gains from Haul Truck Optimization

Data from four optimized haul trucks showed annual fuel savings of 20,342 litres (USD $24,400) and 144 hours of cycle time reduction, resulting in a net benefit of approximately USD $1.03 million after accounting for operating costs.

When scaled to the full fleet of 24 trucks, the estimated annual fuel savings increase to 128,662 litres (USD $154,394), and cycle time gains reach 996 hours. This translates to a total net annual benefit of approximately USD $6.96 million.

Leveraging Ramjack’s technology integration services with Cascadia Scientific’s high-accuracy fuel flow meters and telemetry data to streamline road design, is now a key component in the mine’s operational strategy. These results highlight the substantial value that can be achieved through operational improvements across the haul fleet.

This project proved that by monitoring vehicle health on certain road segments, and improving road conditions, your operations can reduce fuel usage, gain cycle time, and reduce the carbon footprint. The estimated annual fuel savings is based on just improvement of four haul road segments, and the value is greatly increased if they improved further segments of the haul roads. To learn more about Ramjack’s technology integration services, or to schedule a demo, visit us at www.ramjacktech.com.