Underground mine scanning has come a long way recently, but there is still so much more that can be done with this technology. When the use of mobile mine mapping devices like the uGPS Rapid Mapper™ becoming the norm in modern mines, the doors will be opened to new mining practices, like the use of unmanned survey vehicles.

Underground mine scanning has come a long way recently, but there is still so much more that can be done with this technology. When the use of mobile mine mapping devices like the uGPS Rapid Mapper™ becoming the norm in modern mines, the doors will be opened to new mining practices, like the use of unmanned survey vehicles.

Safer Underground Mines

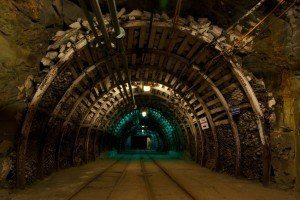

Working in underground mines is, and has always been, a hazardous occupation. To reduce the risks of injuries and fatalities due to mining accidents, it makes sense to reduce the number of people required to work underground. As mine scanning and other related technologies develop, there should be fewer requirements for people to go underground, especially to perform tasks like surveying. Instead, these tasks could be performed by using advanced mine scanners and other devices.

Use of Unmanned Vehicles

One of the key unique features of the uGPS Rapid Mapper™ is that it can collect data while in motion. Usually this is done by attaching the scanner to a vehicle (e.g. a bakkie or rail car) and driving through the mine. However, it is also possible to mount a 3D mine scanner, along with other monitoring and communication devices (e.g. gas sensors) on an unmanned, remotely controlled vehicle. This would allow for the mapping and safety assessment of dangerous parts of a mine without having to put the safety of a miner at risk.

Exploring and Mining at Deeper Levels

So far, mining operations have only explored the upper parts of the earth’s crust. There may well be significant deposits of minerals and metals deeper down, but exploring deep into the earth can be extremely dangerous due to the heat, lack of clean air and the possible presence of toxic gasses. As mine scanning technology advances, it may be possible in the future to use devices like the uGPS Rapid Mapper™ to explore and map out deep-levels, and other areas currently too dangerous for human entry, to determine their suitability for mining.