The application of shotcrete in the world of civil engineering is as ubiquitous as hard hats and steel capped boots. No tunnel or vertical structure is considered stable unless it has a healthy layer of concrete concealing the steel mesh or cable bolts that sit behind.

Despite its necessity, the art of applying the correct amount of shotcrete material is misunderstood with the majority of operators erring on the side of caution and over-spraying; just to be safe. It is reckoned that overspraying by 50% can add an additional 3% to development costs (for an underground mine) – not hard to imagine if the team is being cautious. Overzealous shotcrete teams could be inflating development costs by up to 7% if they overspray twice as what is necessary!

The situation is so common that engineers are resigned to the occurrence and concentrate on other areas. Traditional methods of assessing concrete thickness include using ‘dipsticks’ which are unreliable, even when applied by the most dedicated intern or trainee. The investment in monitoring doesn’t justify the savings that could be realized.

However, with the evolution of 3D scanning, a revolutionary new method has been developed. Originally designed as a mobile 3D point cloud acquisition sensor purpose-built for the underground environment, the UGPS Rapid Mapper™ from Canada’s Peck Tech Ltd., can be used to identify shotcrete overspray and make a significant impact on a mine’s or tunnel’s development costs.

During a visit to an underground gold mine in the US, the Peck Tech team deployed Rapid Mapper™ to a section of tunnel prior to shotcreting. Once the shotcrete had been applied, the team ran the same scan again to gain an understanding of differences in depth of the concrete.

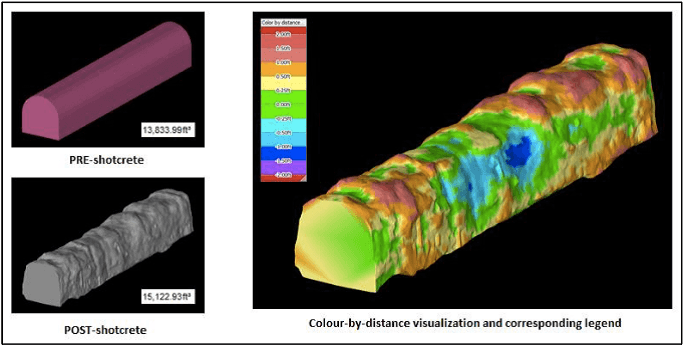

The diagram below illustrates the results of the pre/post shotcrete application:

The image on the right is a colour-by-distance visualization; highlighting the relative depth of the concrete. Peck Tech’s software can also provide a step-bystep cross sectional analysis or simply a volume comparison between the two scenarios.

In this instance, overspray was found to be between 150% and 200% of the original design plan. Over a 15ft section of tunnel, it was estimated that the average cost of over-spraying equated to approximately US$665. Taking into account the increased amount of time required to overspray, coupled with the impact that excess application has on the dimensions of the tunnel, monitoring overspray looks increasingly attractive.

This example was performed in an underground mining environment where dimensions are kept to a minimum; in other tunnel environments where room for cars, metros or other vehicles are required, the potential savings are significantly more.

Utilising Rapid Mapper™ in your tunneling operation will help focus the shotcrete teams’ performance to more accurately follow the tunnel plan. Not only can Rapid Mapper™ help shotcrete teams minimize overspray, but the images will provide confidence that the job has been done safely; within the parameters called for in the design.

Beyond overspray monitoring, Rapid Mapper™ assists in numerous areas of tunnel development, including:

- Convergence monitoring

- Raise/Shaft monitoring

- Stope Reconciliation

- Ventilation: Detailed Roughness Factor Modelling

- Rapid Development ‘pick-ups’ or ‘as-builts’

- Rapid Open-loop 3D Mapping

Rapid Mapper™ is a cost effective alternative to traditional LIDAR based stationary solutions. In the instance described above, realized savings would pay for a single unit in less than half a mile of tunneling.

For further information, please contact Rupert@ramjack.co.za